The world's population is growing and on average is getting richer. This also increases the demand for plant or animal proteins. But the production of such proteins requires a lot of land and water. It also releases a lot of CO2, methane and nitrogen. The greenhouse gases contribute to global warming. "We calculated how much protein will be needed in 2050," says Henk Noorman of dsm‑firmenich and TU Delft. "If the world population grows by two billion people, and the middle class continues to grow, at least 50% more protein than today will be needed. It is not possible to make this in a traditional way."

Our microbes have a high protein content

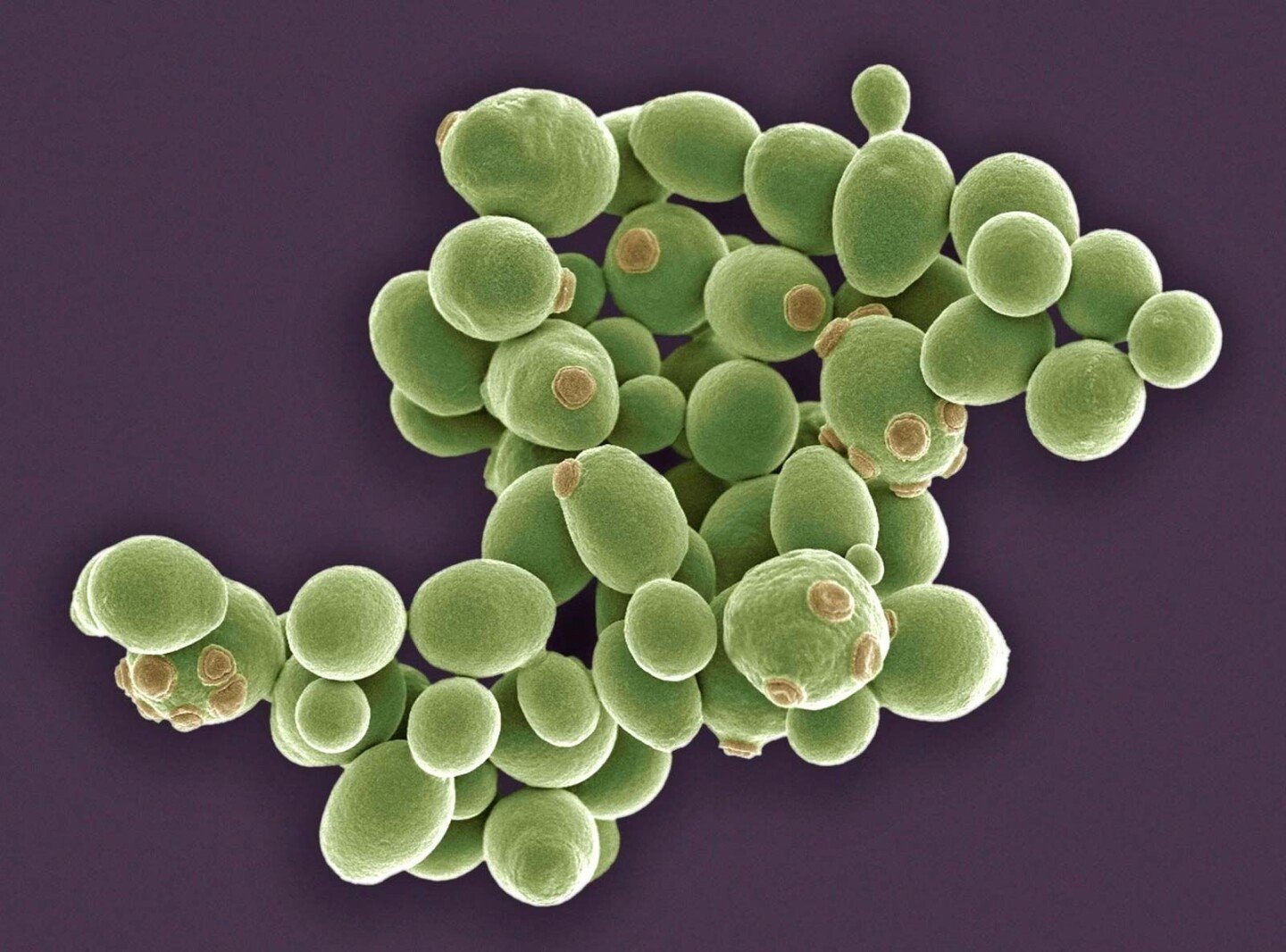

'In a traditional way' means getting the protein from plants, such as soy. Or getting it from animals, such as cows or fish. The world is already running up against limits here, but if production needs to be increased, this means even more deforestation, overfishing and CO2 in the air. "We can do something about this with alternative proteins," says Noorman. "Protein can be obtained from fungi, yeasts or bacteria. These have a high protein content. At the Biotech Campus Delft, we know better than anyone how to grow yeasts in a controlled manner. We have been doing this for over 150 years. But protein alone as a meat or dairy substitute isn't enough, you also need to make it into a tasty and healthy product, such as a burger. And that requires, among other things, fragrances and flavorings. We are also developing and producing those here."

Demonstration plant

dsm‑firmenich is therefore in the perfect starting position to develop and produce such proteins. "We have been working on it for years and have carried out successful tests," says Noorman. "Together with our partners, we now want to scale up to a demonstration plant. We are looking for a suitable location." This could be in the Netherlands, but also elsewhere in the world. "It depends on technology, financing and regulations." dsm‑firmenich is looking at Rotterdam and Amsterdam as options. "We are looking for chemical companies that produce 'green molecules' from CO2 and green electricity. These are the raw materials we need for our production process, together with green nitrogen." A major additional benefit is that microbes help to convert greenhouse gases into protein — a positive contribution to the environment.

Good for the Netherlands

"The Netherlands can benefit greatly from this," says Noorman. "Via the energy transition, we are now moving toward the protein transition, and that can be a great thing." There is one bottleneck, however: The green power required is still very expensive. "We are hoping that the government will make a transitional contribution, to ensure a healthy business case. We don't want to wait ten years for sufficient and affordable green power to be available, because then we will be too late." After all, our competition is not standing still. Innovative solutions to the protein shortage are being developed all over the world. Including at the Biotech Campus Delft. "Here, companies are working on other solutions, such as dairy substitutes, new plant proteins, cultured meat or proteins from bacteria. Examples include Vivici, Proeon and Meatable, the latter having now moved elsewhere to continue its growth." Does Noorman see these companies as competitors? "Of course, but also as potential partners. In our view, it is good to share knowledge, because this will always make you better. You give something, but you get more back. And there's plenty of room for everyone."

On the shoulders of Van Marken

"If it is up to us, the demonstration plant will be up and running in four to five years. We can then carry out test runs, so that we will be on the market by 2030." Noorman is enthusiastic. "The need is enormous; we can really have an impact. The energy is good!" He also finds it amazing to be able to stand on the shoulders of a giant from Delft. "In this exact place 150 years ago, Jacques Van Marken made yeasts that enabled bakers to make good and stable bread. So, in a certain sense, we are going back to our 'roots.' I think that's great."